- Ferrous Foundry

- ARPA 450 Jolt and Squeeze type molding Machine

- DT7 or Equivalent ARPA 1300 Jolt and Squeeze Type Molding Machine

- Sand Test Laboratory

- CNC Machining facilities in house and Out-Source

Ferrous Foundry

- Dual Track Induction Furnaces Make INDUCTOTHERM Capacity 500 KGS.

- Dual Track Induction Furnaces Make INDUCTOTHERM Capacity 750 KGS.

- Automated Sand Plant Capacity 15 Tons/Hour.

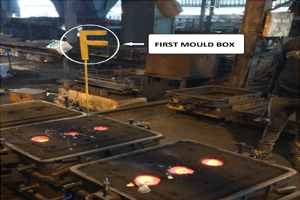

- Automated Molding Machines Make DISA Capacity 700 X 600 mm Molding Box and DT7 capacity1100X950 mm Molding Box.

- No Bake Core in Acid, Easter base & Co2 system

- Shell Core Shooter Make SUSHA FOUNDERS.

- Hanger Type Shot Blasting Machine Make DISA.

- In House Design Section with Design Tools Like SOLID WORKS, AUTO CAD.

- Modernized Laboratory with Spectrometer, Image Analyser & Metallurgical Microscope, Sand Testing Facilities.

- Unit 2: Machining Facilities Equipped with VMC & CNC Machines.